Microlino

2014-2015. My first production project. Great times, fantastic crew.

The birth of the Microlino

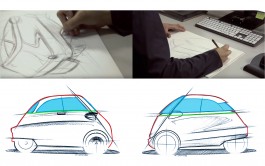

The project started back in 2014 as a collaboration between Designwerk, Micro and Zurich faculty ZHAW. The ZHAWs students' assignment was to design a battery-electric substructure for a new type of cabin scooter. Simoltaneously, I was in charge of designing the bodywork. Micro CEO Wim Ouboter's briefing was straightforward: it had to be retro and chic, modern but unmistakably a cabin scooter - with a front door, obviously.

I started with a white sheet of paper and quickly went on to building a 3D model, which was finally printed in 1:4-scale. Nobody was thinking about serial production at this stage.

My approach was as follows:

1. The vehicle should be about 120mm wider, longer and taller than its predecessor from the Fifties.

2. The rear track should be significantly wider to ensure better driving stability.

3. The body and the greenhouse should be one visual entity, separated by an undercut

4. From anti-wedge to wedge

5. The DLO should wrap around the body seamlessly. A and B pillars painted in black.

Prototype N1

While the enthusiasm for the project increased among the team, Micro decided to have a functional prototype of the car built. The company made capital of its long-time manufacturing experience in the far east and got in touch with a Chinese prototype producer. The quite rudimentary first full-scale model of the vehicle was an approximation to the final design and was hand-crafted in a relatively short time. The complete prototype served initially for test purposes, especially ergonomics and performance. It was exhibited at various motor shows, including GIMS Swiss. The construction was largely based on the package developed by the ZHAW students. A member of the team, Pascal Studerus, was taken over by Micro and supervised the project in China and in the further course of development.

The Pre-Series

After a successful world premiere in Geneva in 2016 and over 1,000 reservations in just two weeks, Micro went in quest for finding a manufacturer. In order to level up the vehicle to production maturity, a cooperation with Tazzari was established. The Italian carmaker specializes in small electric vehicle and builds engine parts for italian performance car brands.

In January 2018, Micro presented the first pre-series Microlinos, with an official European homologation as L7e vehicle. To date (Feb 2020) a total of 30 pre-series Microlinos are being tested, while the number of reservations amounts to approximately 16,000. Production is scheduled to start in 2021 with a facelifted version.

To stay true to the original, ingress is through the front while the steering wheel retracts with the door. Microlino is considered a light vehicle in the L7e class and is not constraint to meet prevailing crash tests. The vehicle offers features such as heating, a Bluetooth audio system, wipers and opening windows.

With its compact dimensions of LxWxH 2435mm x 1500mm x 1469mm, the Microlino is agile and conveys pure driving pleasure.The short overall length enables it to park at right angles to the direction of travel. The fabric folding roof creates a Mediterranean flair and also serves as an emergency exit. The Microlino accelerates to 50 in 5 seconds, has a top speed of 90km / h and is available in two battery options with 125km / 200km of range.

The cargo area is accessible through a glass trunk and has a capacity of 220 liters. In order to reduce the number of components, the headlight module also houses the side mirror. The interior is dominated by a two-seat bench. The dashboard consists of a body-color part and dispenses of anything but a speedometer and an instrument panel.

Microlino

2014-2015. My first production project. Great times, fantastic crew.

The birth of the Microlino

The project started back in 2014 as a collaboration between Designwerk, Micro and Zurich faculty ZHAW. The ZHAWs students' assignment was to design a battery-electric substructure for a new type of cabin scooter. Simoltaneously, I was in charge of designing the bodywork. Micro CEO Wim Ouboter's briefing was straightforward: it had to be retro and chic, modern but unmistakably a cabin scooter - with a front door, obviously.

I started with a white sheet of paper and quickly went on to building a 3D model, which was finally printed in 1:4-scale. Nobody was thinking about serial production at this stage.

My approach was as follows:

1. The vehicle should be about 120mm wider, longer and taller than its predecessor from the Fifties.

2. The rear track should be significantly wider to ensure better driving stability.

3. The body and the greenhouse should be one visual entity, separated by an undercut

4. From anti-wedge to wedge

5. The DLO should wrap around the body seamlessly. A and B pillars painted in black.

Prototype N1

While the enthusiasm for the project increased among the team, Micro decided to have a functional prototype of the car built. The company made capital of its long-time manufacturing experience in the far east and got in touch with a Chinese prototype producer. The quite rudimentary first full-scale model of the vehicle was an approximation to the final design and was hand-crafted in a relatively short time. The complete prototype served initially for test purposes, especially ergonomics and performance. It was exhibited at various motor shows, including GIMS Swiss. The construction was largely based on the package developed by the ZHAW students. A member of the team, Pascal Studerus, was taken over by Micro and supervised the project in China and in the further course of development.

The Pre-Series

After a successful world premiere in Geneva in 2016 and over 1,000 reservations in just two weeks, Micro went in quest for finding a manufacturer. In order to level up the vehicle to production maturity, a cooperation with Tazzari was established. The Italian carmaker specializes in small electric vehicle and builds engine parts for italian performance car brands.

In January 2018, Micro presented the first pre-series Microlinos, with an official European homologation as L7e vehicle. To date (Feb 2020) a total of 30 pre-series Microlinos are being tested, while the number of reservations amounts to approximately 16,000. Production is scheduled to start in 2021 with a facelifted version.

To stay true to the original, ingress is through the front while the steering wheel retracts with the door. Microlino is considered a light vehicle in the L7e class and is not constraint to meet prevailing crash tests. The vehicle offers features such as heating, a Bluetooth audio system, wipers and opening windows.

With its compact dimensions of LxWxH 2435mm x 1500mm x 1469mm, the Microlino is agile and conveys pure driving pleasure.The short overall length enables it to park at right angles to the direction of travel. The fabric folding roof creates a Mediterranean flair and also serves as an emergency exit. The Microlino accelerates to 50 in 5 seconds, has a top speed of 90km / h and is available in two battery options with 125km / 200km of range.

The cargo area is accessible through a glass trunk and has a capacity of 220 liters. In order to reduce the number of components, the headlight module also houses the side mirror. The interior is dominated by a two-seat bench. The dashboard consists of a body-color part and dispenses of anything but a speedometer and an instrument panel.